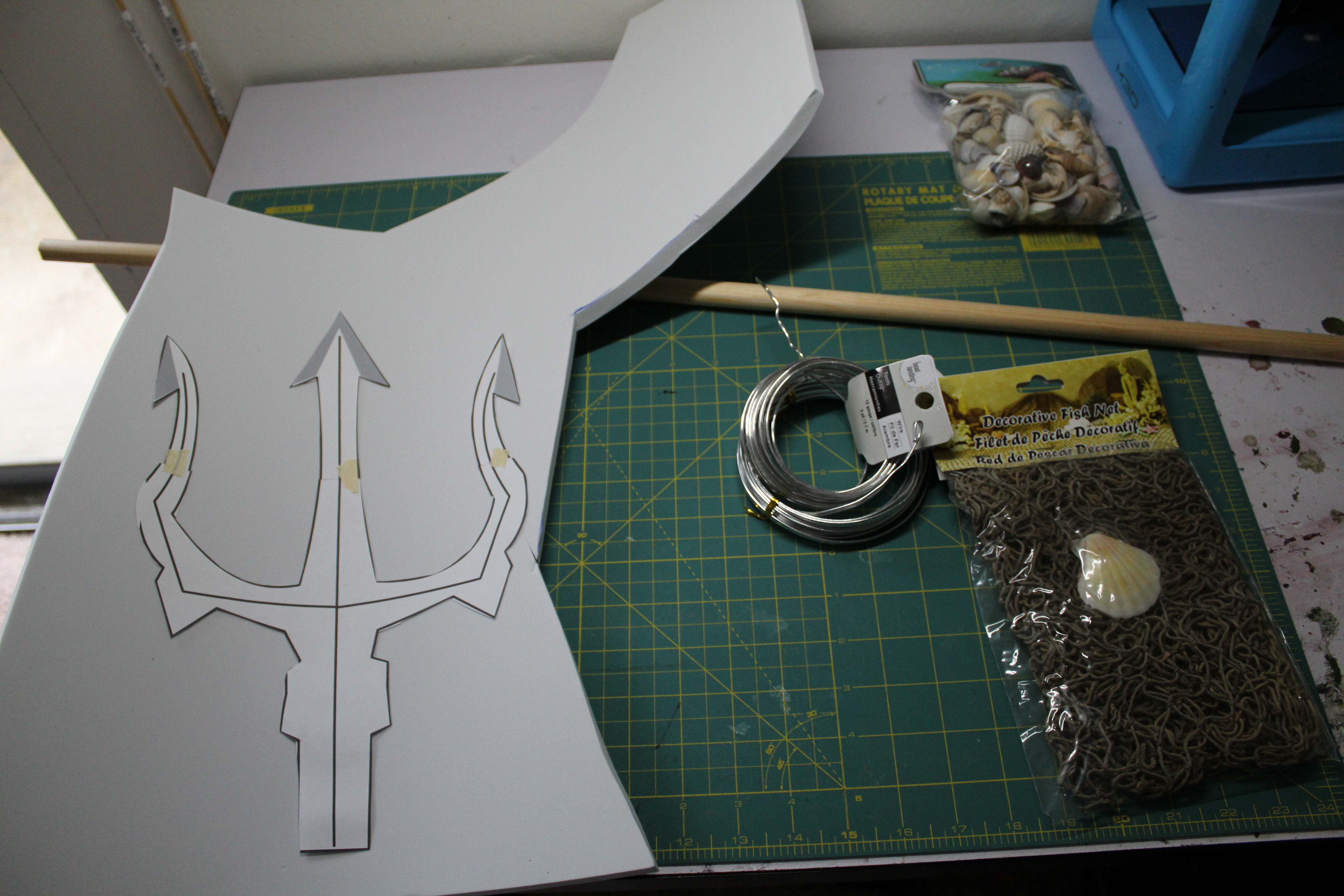

Build Materials

- Pattern of Trident

- 10mm or 6mm Craft Foam

- Heat Gun

- Dowel Rod

- 12g Wire or thicker

- Paints- silver, green, purple

- Plasti Dip

- Contact Cement

- Super Glue

- Box cutter

- Sea shells and fishing net

- Dremel Tool with Sanding bits

- Worbla (optional)

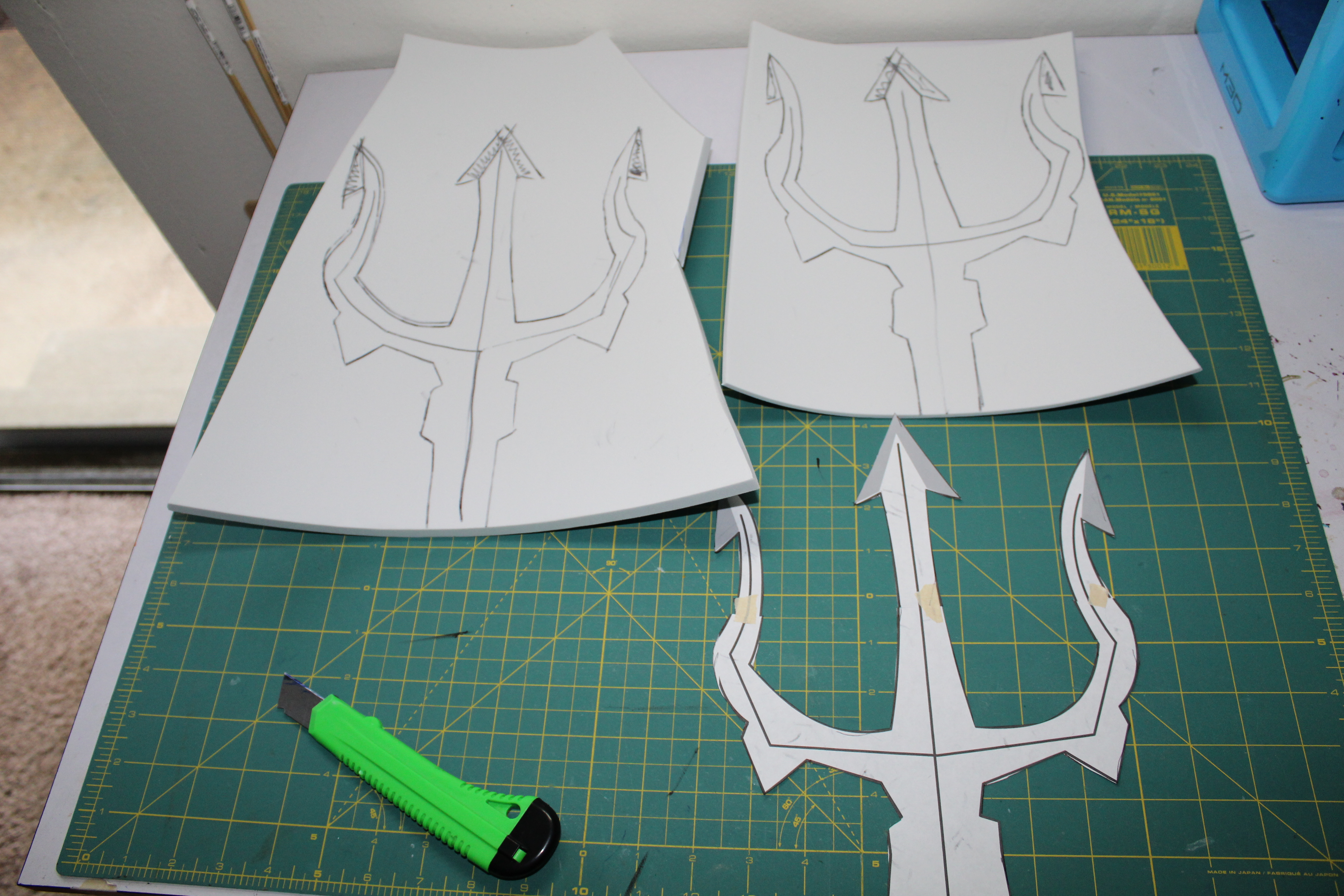

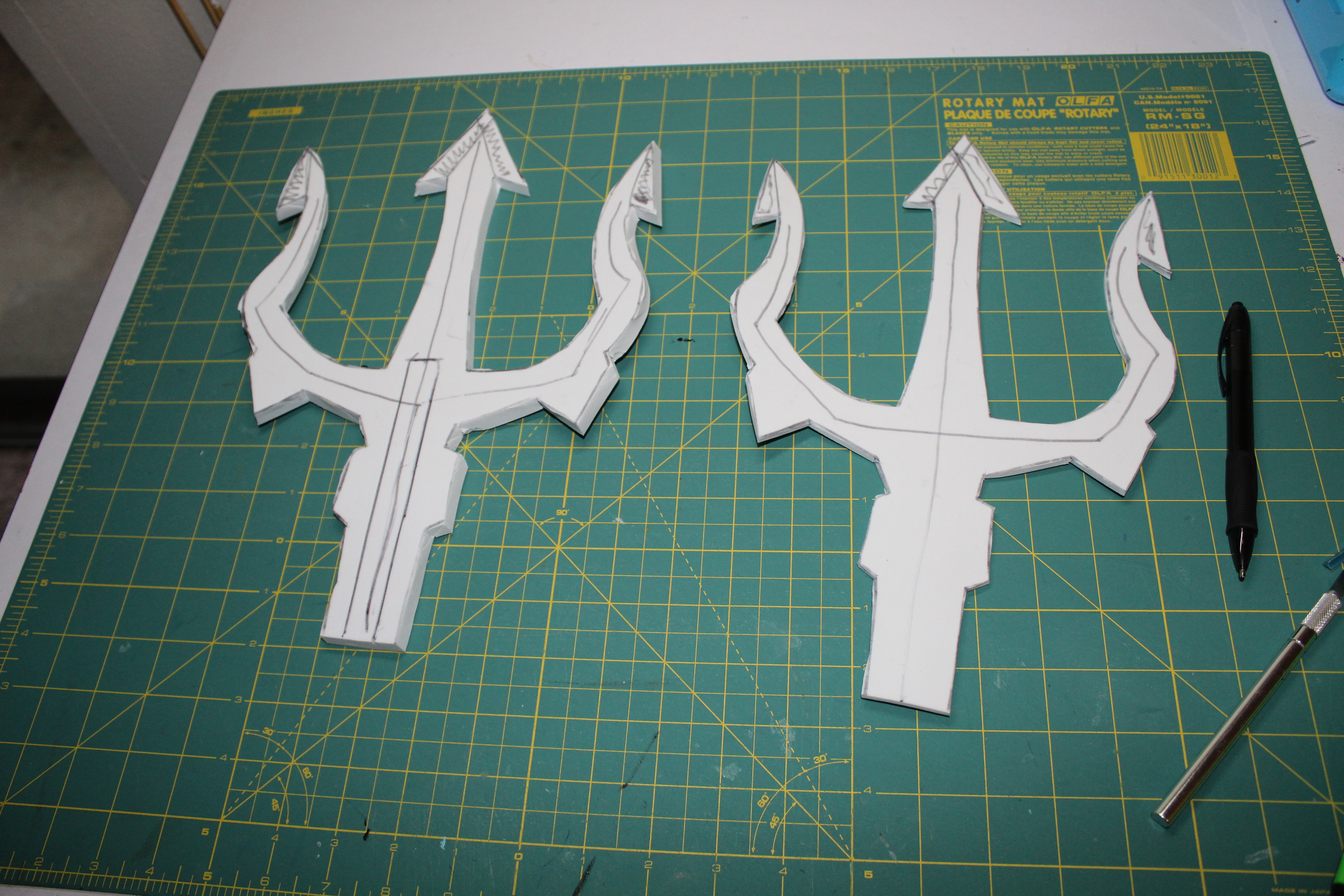

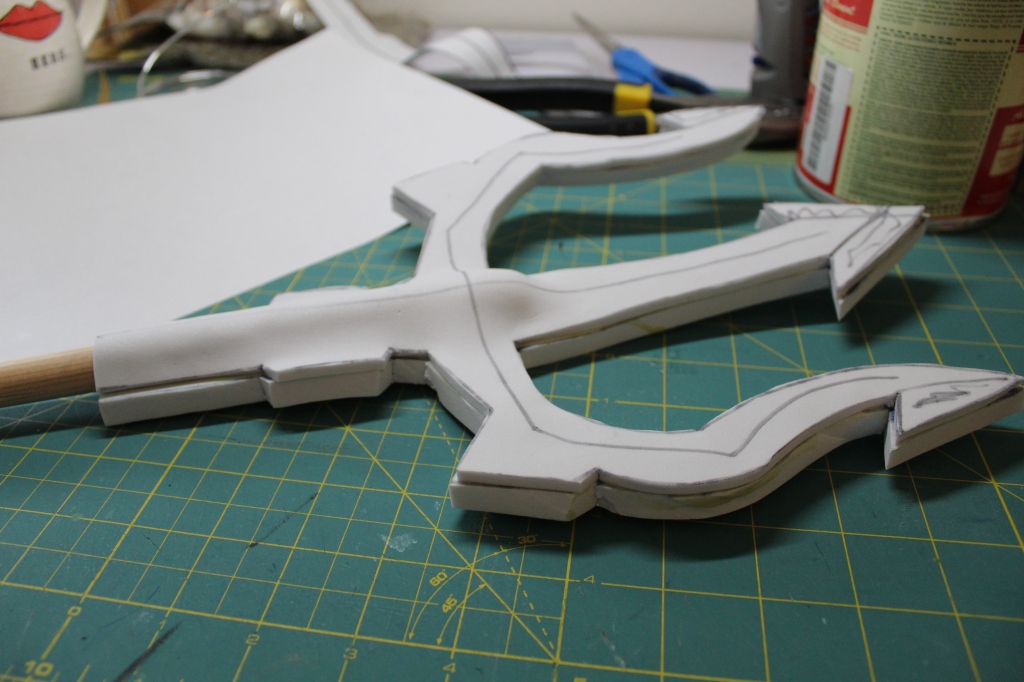

- Trace your pattern on to your craft foam. You will need 2 of these.

2. Cut them out using your box cutter. (Sharpen the blade if you fell the foam pulling during your cuts.)

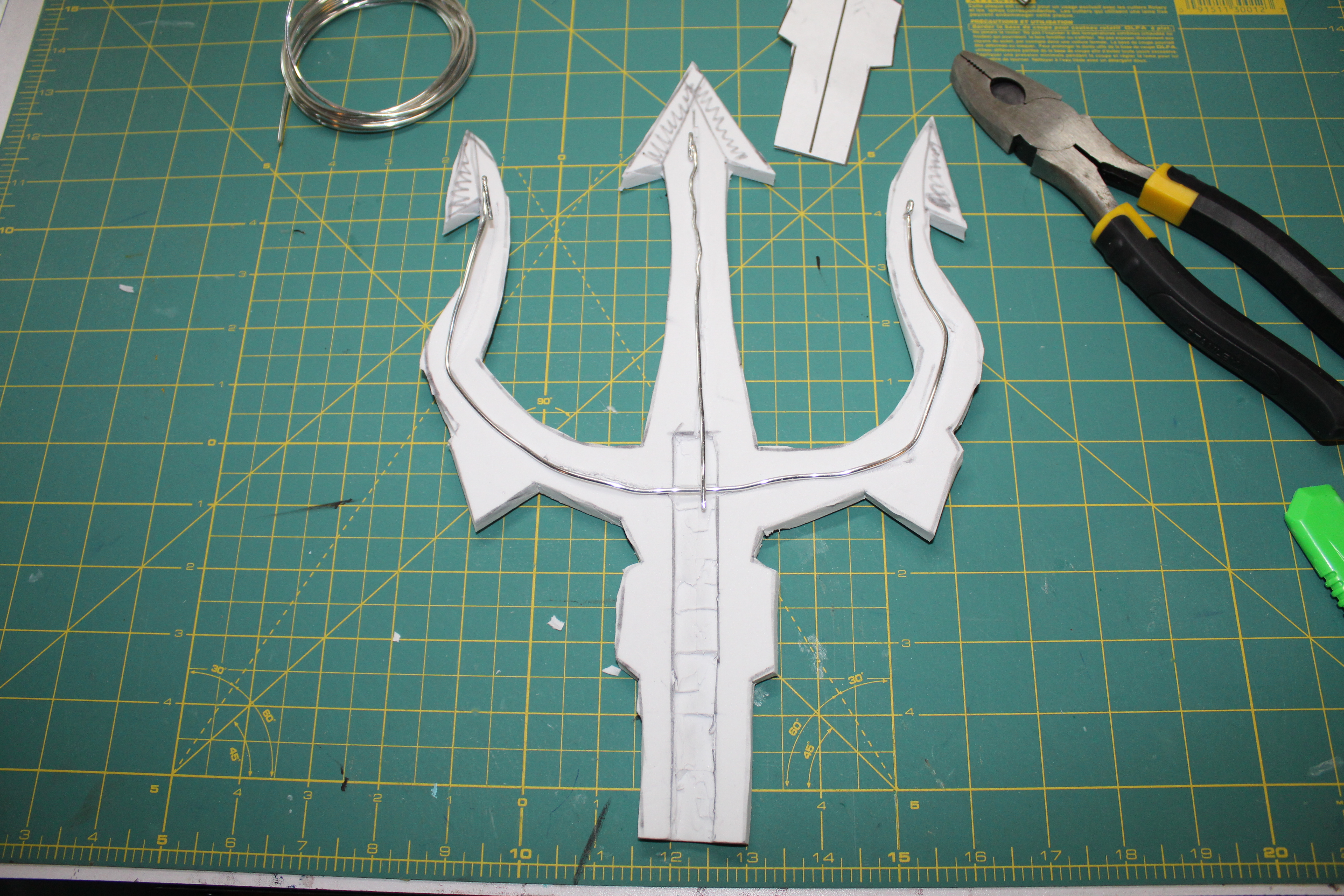

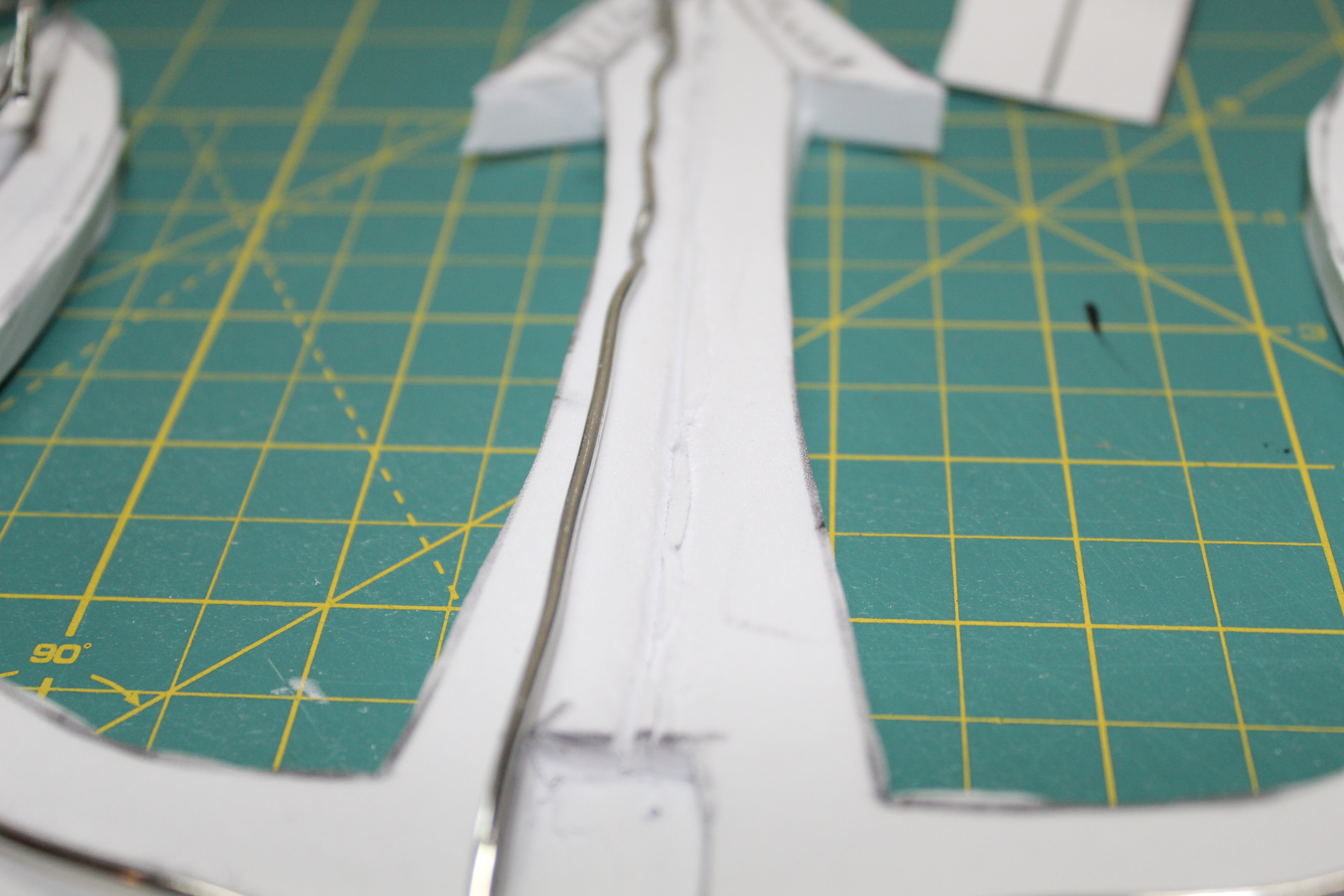

3. Bevel out areas for the wire and the dowel rod on one of your foam pieces. The bevel should be big enough to fit the wire and the rod. Try not to go through the other side of the foam. (If you do happen to cut through the other side it can be patched with super glue.)

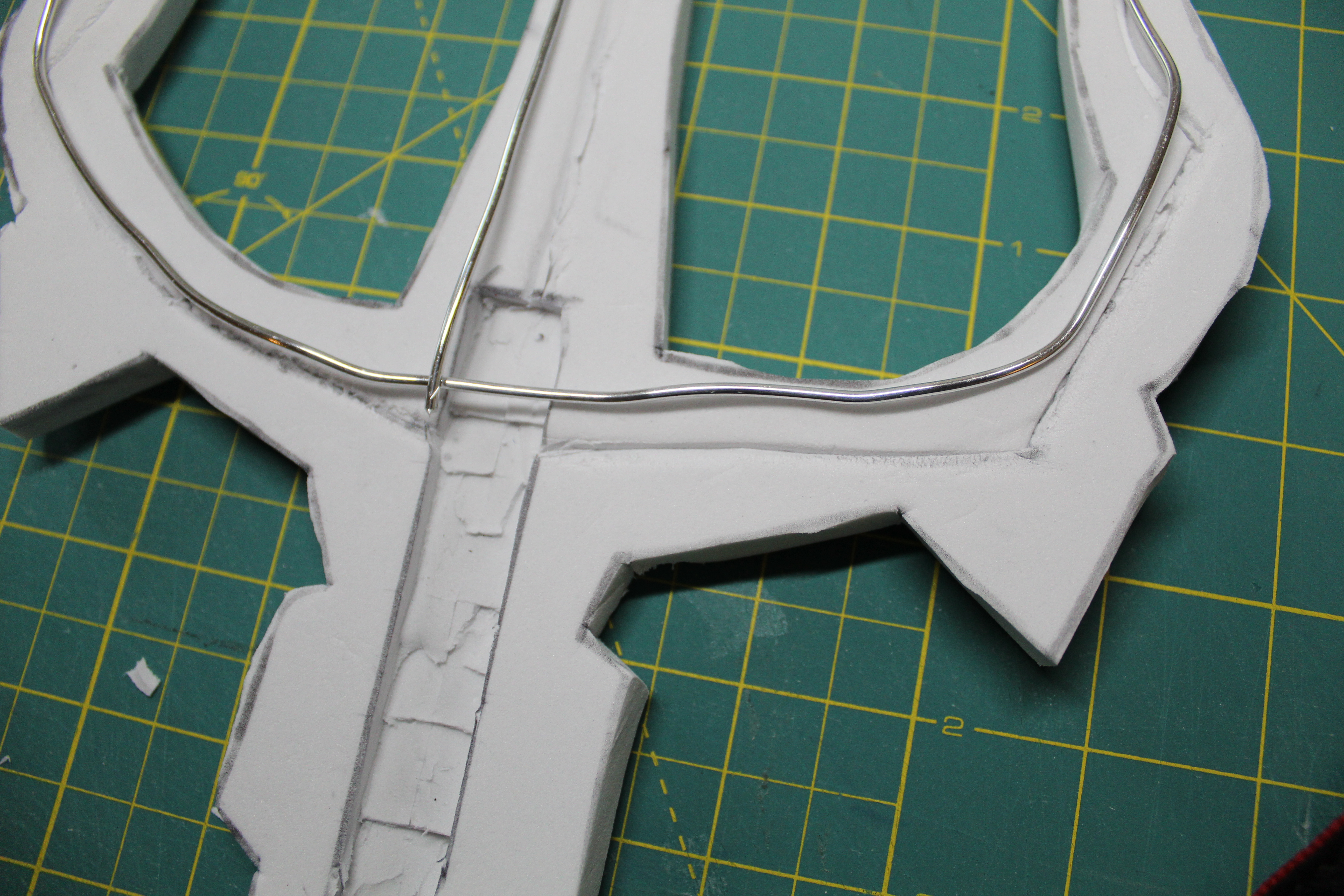

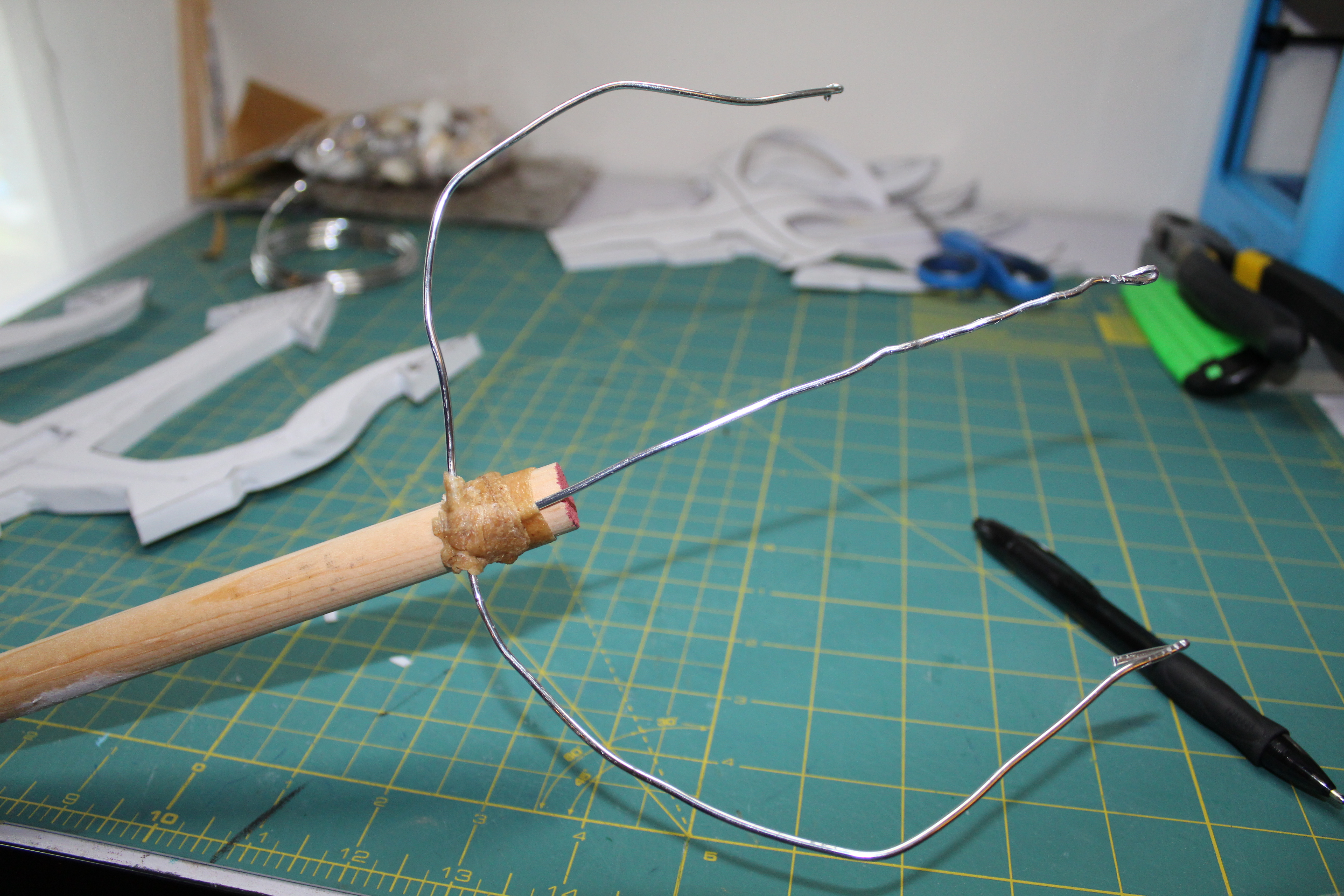

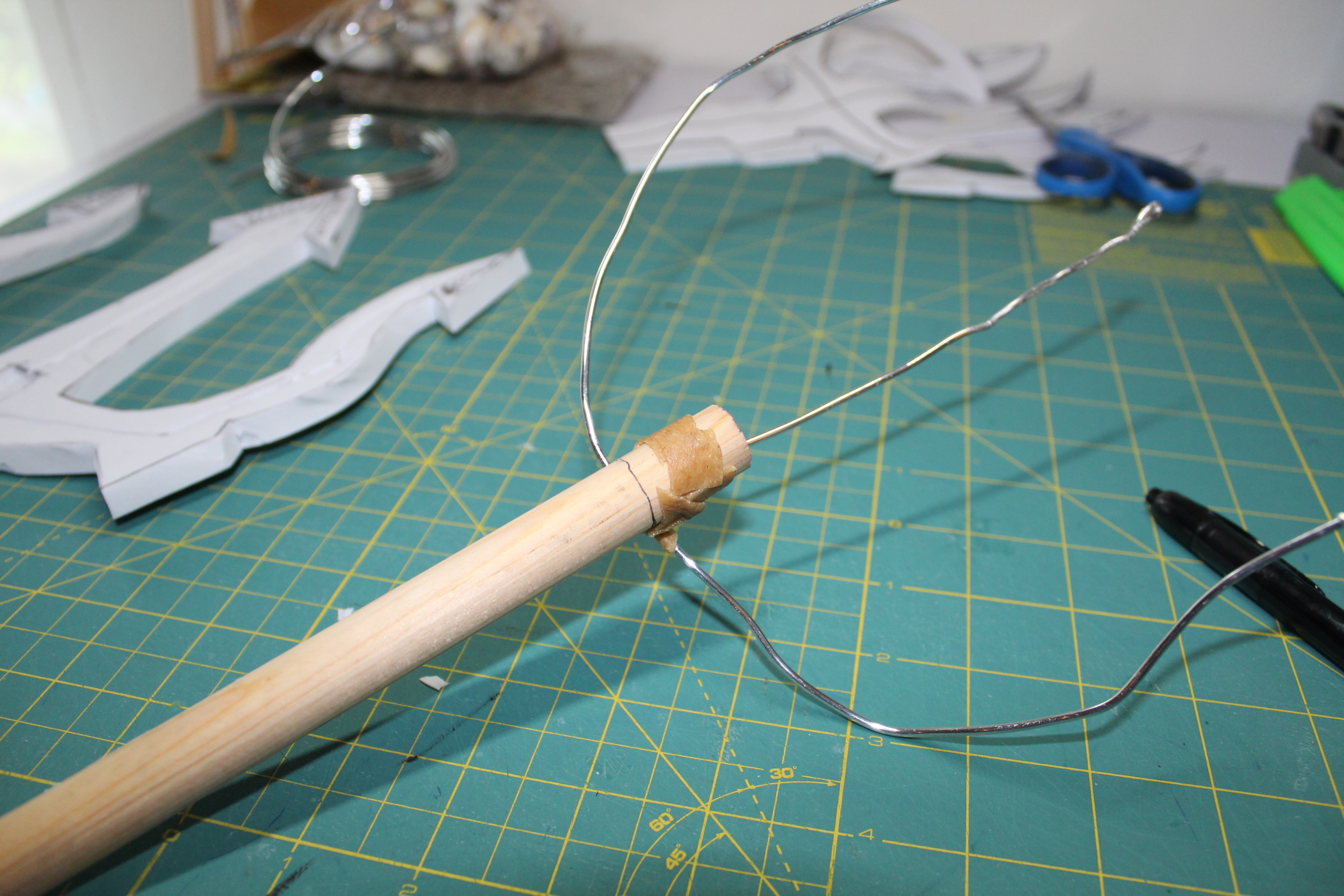

4. Try test fitting your wire. Cut and bend until you get the fit you want.

5. Once you get wire to the length and the bends the mirror the foam piece attach the wires to your dowel rod. I had some left over Worbla to attach the wire to the rod. On another test. I tried ruffing up the wire with sand paper and used super glue and it seemed to work just fine.

6. After the wires were secure I applied 2 layers of contact cement into the dowel rod area and two layers on the dowel rod itself. Once the contact cement was dry push the rod onto the foam piece.

7. After the dowel rod is secured push the wires into their beveled areas. Once you have them pushed in you can secure them with super glue. You can be pretty generous with the glue. You don’t want the wires moving around.

IMG35

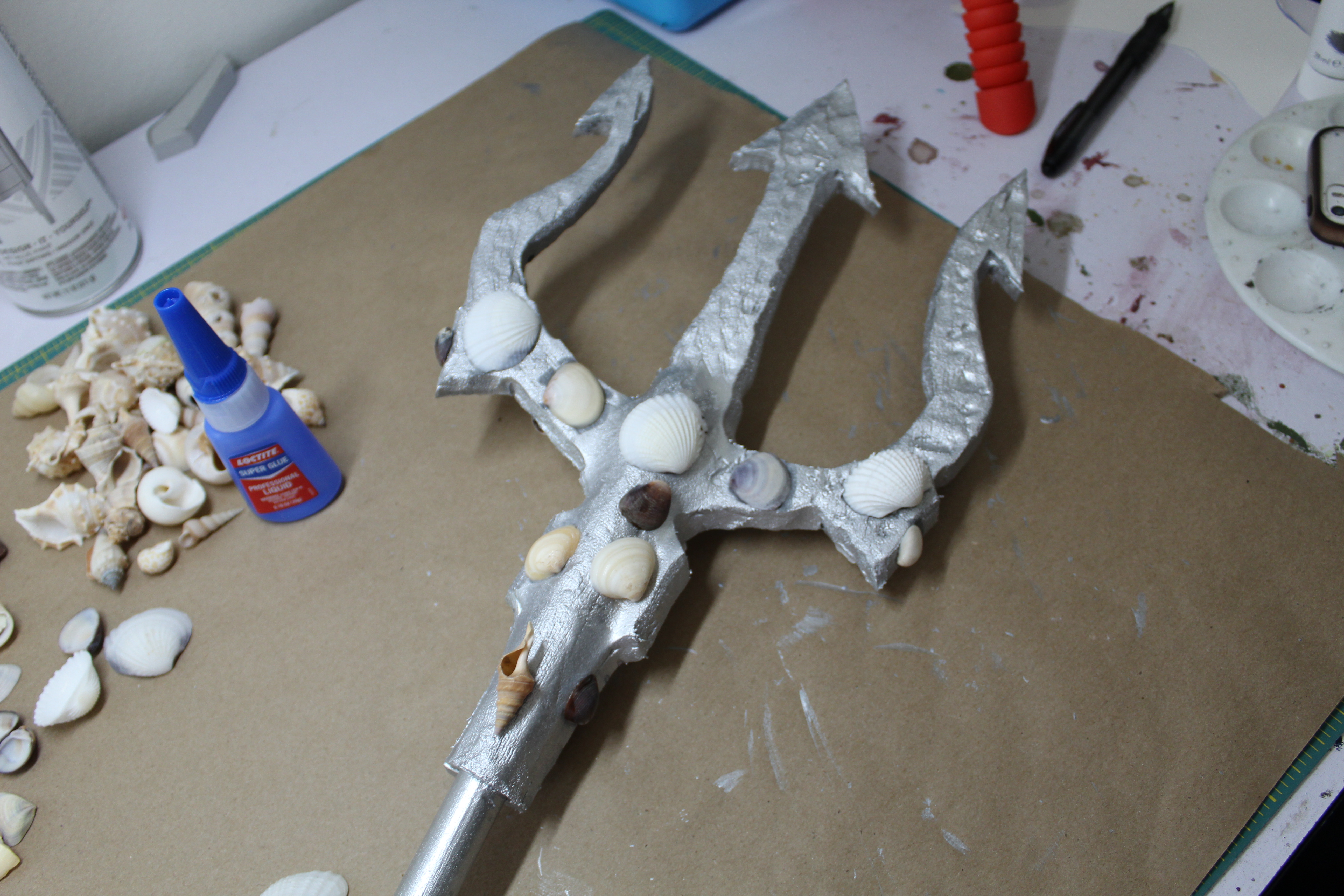

8. Once the super glue is all dried lather up the trident with contact cement and one side of the other foam piece. Let the cement dry before you start to sandwich the together. If not then the pieces can slide around and we don’t want that. You may have to put a piece of paper between the prongs when pushing these together. Work one prog at a time. You only get one shot doing this part so you want both side to match up at this point as much a possible.

9. After the foam tridents are secured to each other and the contact cement is fully set you can do some clean up with the dermal tool with a sanding bit. You can smooth out the edges and add texture. I wanted to go for more of a stone look with ruff texture. (Laying down a damp paper towel helped contain some of the dust. But always ware a safety mask when sanding foam)

10. Once you get the texture and the same you like you need to heat seal the foam with your heat gun. This will close all the small holes and help get rid of any unwanted fuzzies from the sand process. You will also want to seal your foam before you paint. I used Plasti Dip for this prop. I hit all the foam with 3 layers and let dry over night before I started painting.

11. I then covered the entire trident in 3 layers of silver paint.

12. I then super glued some sea shells onto some of the foam areas.

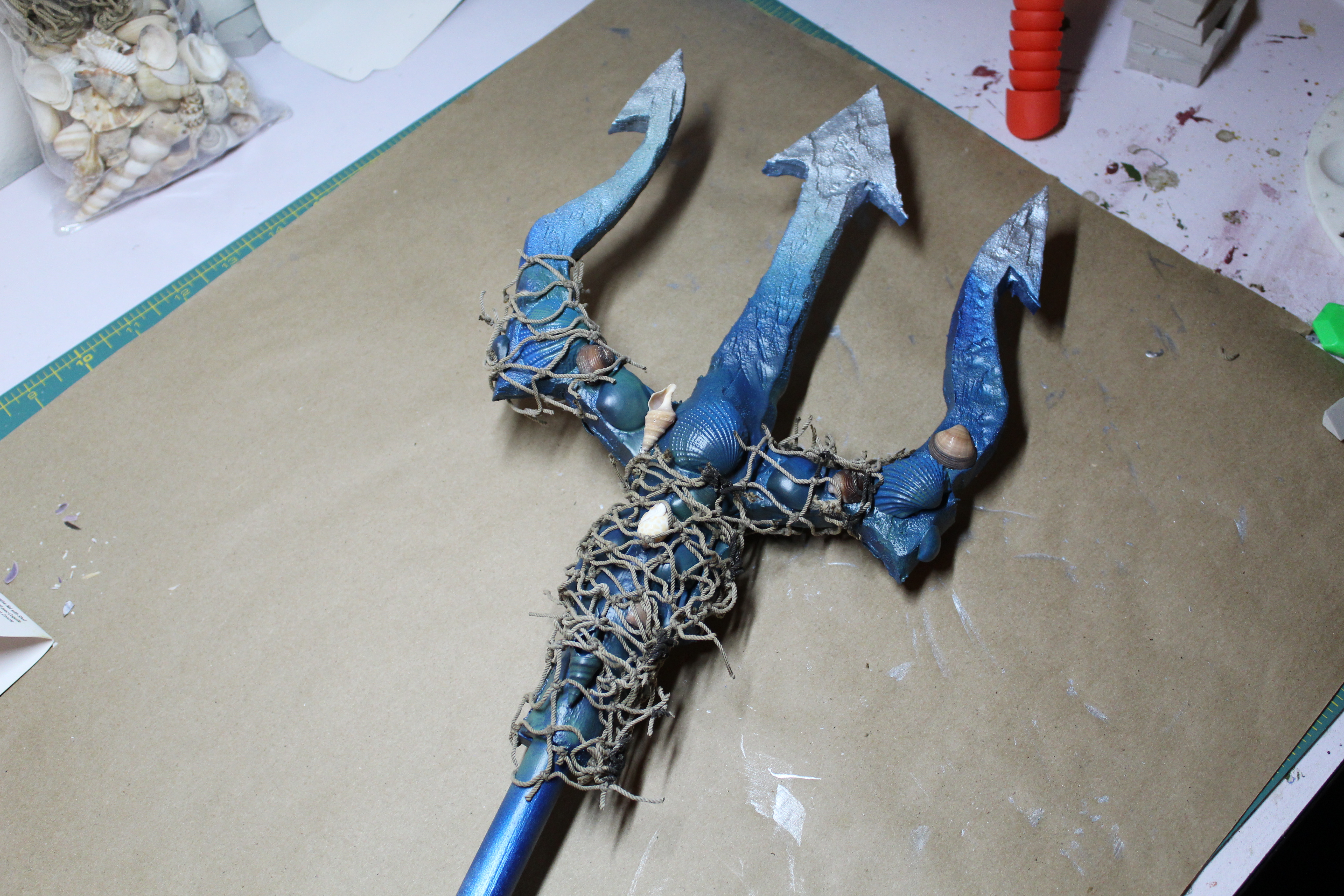

13. I then went in with my blue and Sea Foam Green paint for accent colors.

14. I went back and super glued more sea shells on the tridents.

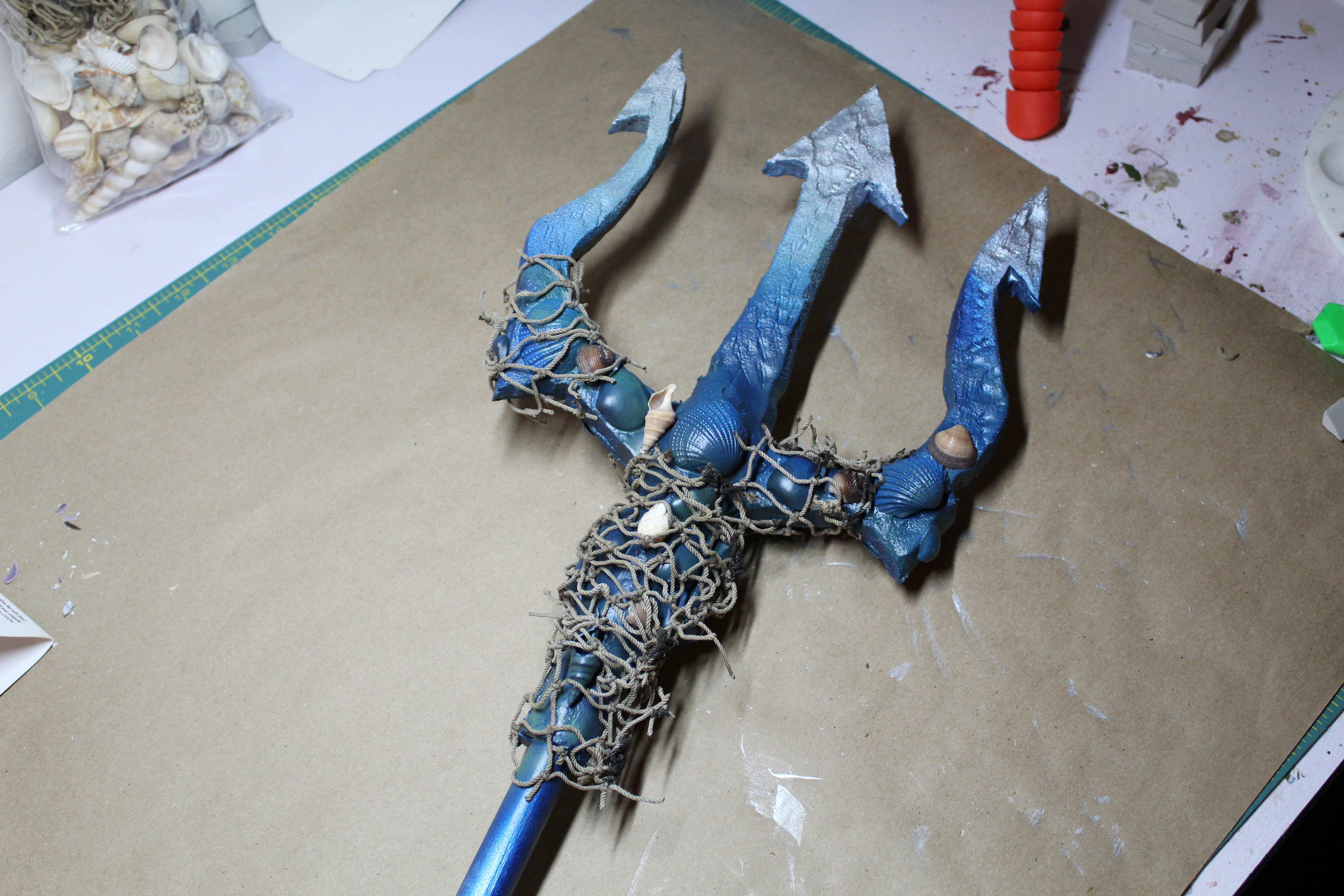

Last thing was to add the fishing net. I just cut off sections and tied them to one another and secured each knot with superglue. Let the super glue dry overnight and you have yourself a trident.

I was skeptical until I saw the fishing net, but that made it look so real. Well done!

LikeLike

Can’t leave off the finishing touches.

LikeLike